Explain Different Parts and Uses of Process Control Block

The simplest form of a block diagram is the block and arrows diagram. 1 it accepts data or instructions by way of input 2 it stores data 3 it can process data as required by the user 4 it gives results in the form of output and.

For this task the process control block PCB is used to track the processs execution status.

. A process can be new ready running waiting etc. This component includes accumulators index and general-purpose registers and information of condition code. PCB contains Process-Id Process State Process Priority Accounting Information Program Counter and also some other information which helps in controlling the operations of the process.

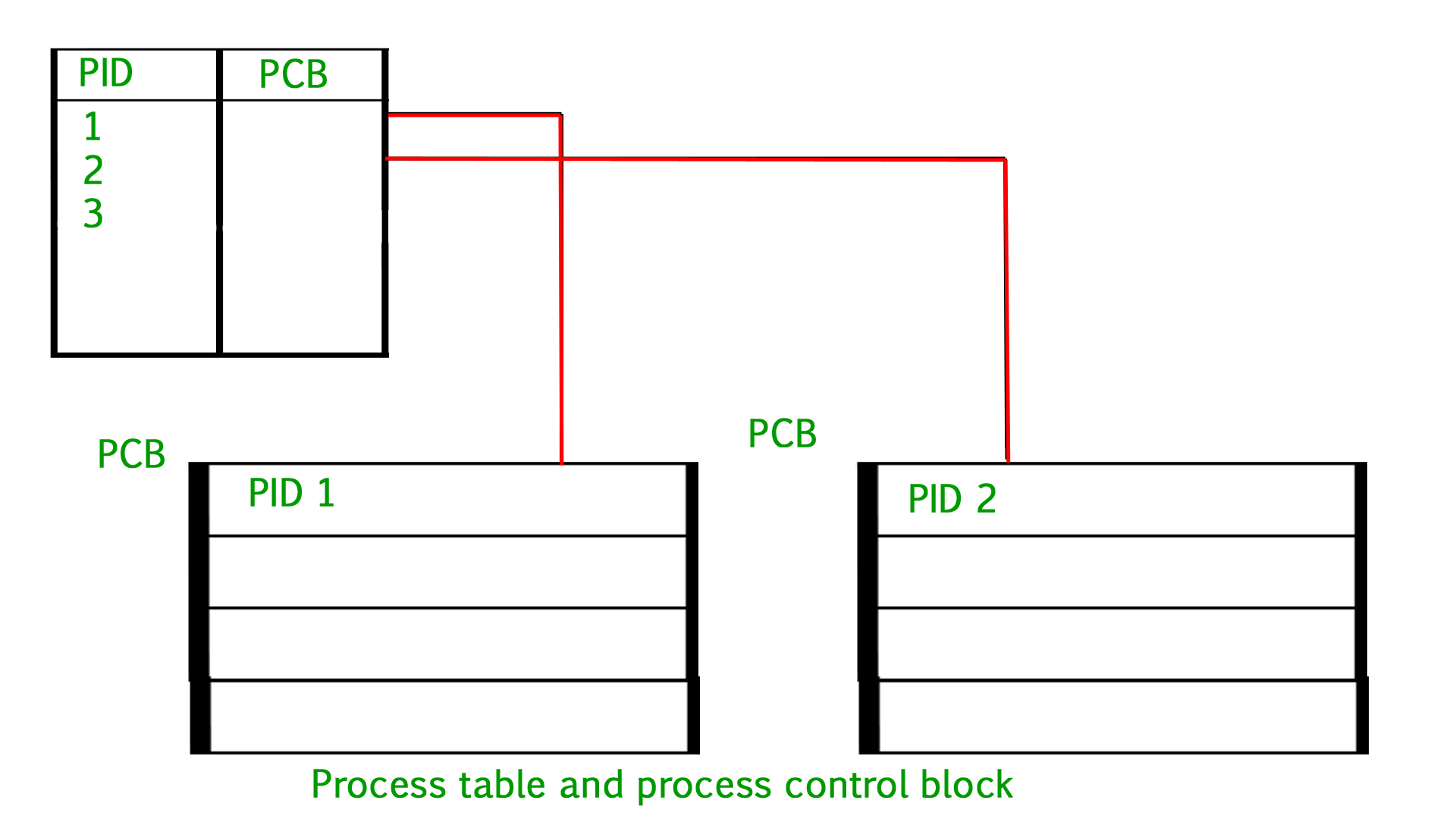

So that Every Process may also Contains Some Child process. When a process is created the operating system creates a corresponding process control block. The Process Control Block of a process looks like-.

ThePCBincludes a memory map list of open files and environment variables. This information is required by the CPU while executing the process. So each process will be given a PCB which is a kind of identification card for a process.

While studying one it is very crucial to keep in mind that a block diagram only represents flow paths of control signals. A block diagram is a pictorial representation of the cause and effect relationship between the input and output of a physical system. It is used to display the essential elements of the system through simple and clear interconnectedness.

The process control block has many fields that store the relative information about that process as you can see in the above figure. Allocating and managing the memory map is typically the most time-consuming activity. It consists of a single block with one input.

Executive Process Block EPROCESS includes KPROCESS and PEB. Creating a process requires allocating a process control block PCB a rather large data structure. It is used in industry to maintain quality and improve performance.

In this controllers are distributed throughout the entire plant area. Allocating and managing the memory map is typically the most time-consuming activity. All these information is required and must be saved when the process is switched from one state to another.

Each block of memory contains information about the process state program counter stack pointer status of opened files scheduling algorithms etc. Creating a process requires allocating a process control block PCB a rather large data structure. It is also called as context of the process.

Compared to this the program code is only the text section. Allocating and managing the memory map is typically the most time-consuming activity. So that we can say that a Process which is given to the System is also known as the Parent Process and all the other Parts of the Single Process are known as the Child Process.

The role or work of process control block PCB in process management is that it can access or modified by most OS utilities including those are involved with memory scheduling and input output resource accessIt can be said that the set of the process control blocks give the information of the current state of the operating system. Block Diagrams for Process Control The third block diagram example is of a feedback control system. Each process is identified by its own process control block PCB.

A process control block is a data structure used by computer operating systems to store all the information about a process. Creating a process requires allocating a process control block PCB a rather large data structure. The program counter lets you know the address of the next instruction which should be executed for that process.

A block diagram provides a means to easily identify the functional relationships among the various components of a control system. A process passes through different states as it executes. Distributed Control System is a specially designed control system used to control complex large and geographically distributed applications in industrial processes.

The PCB includes a memory map list of open files and environment variables. Process Control Block PCB Process state. 3 Operating Systems Lecture 06 page Windows NT PCBs Information is scattered in a variety of objects.

When the temperature of the room is too low the thermostat will turn on a heating. The PCB includes a memory map list of open files and environment variables. This specifies the process state ie.

Process control is the ability to monitor and adjust a process to give a desired output. New ready running waiting or terminated. A Single Process may also contain sub Processes those are also known as the Child Process.

A Process Control Block or simple PCB is a data structure that is used to store the information of a process that might be needed to manage the scheduling of a particular process. It can also be said as a program that is under execution. Role of process control block.

Process Control Block PCB is a data structure that stores information about a particular process. A process is an active program. Control information normally consists of the process identifier process status address in memory of next instruction to be fetched saved.

UNIX process parts The PCB is the box labelled process structure but the user structure maintains some of the information as well only required when the process is resident. 5 it controls all operations inside a computer. These distributed controllers are connected to both field devices and operating PCs through high-speed.

Many types of process control systems exist including supervisory control and data acquisition SCADA. It is also known as a process descriptor. It is more than the program code as it includes the program counter process stack registers program code etc.

Process control systems PCS sometimes called industrial control systems ICS function as pieces of equipment along the production line during manufacturing that test the process in a variety of ways and return data for monitoring and troubleshooting. The operating system builds such information either into a table of such control information in which case the process identifier is normally the number of its position in the table or in a free-standing process control block held in memory. An example of a simple process that is controlled is keeping the temperature of a room at a certain temperature using a heater and a thermostat.

Process Table And Process Control Block Pcb Geeksforgeeks

Comments

Post a Comment